What is Contract Manufacturing – Definition?

A quick definition of Contract Manufacturing. Contract manufacturing is a form of outsourcing when a contract manufacturer enters an agreement with a hiring company to manufacture certain subassembly or complete products according to the hirer’s design and specification over a specified period of time.

Why Outsource to Contract Manufacturer?

Total in-house production required lots of resources and capability. Investing in facilities, equipment, machinery, and human resource can be costly. For these reasons, contract manufacturing is a viable option, it enables the hiring company to begin selling their products without investing to build and run a factory.

How Does Contract Manufacturing Work?

The hiring company usually provides a design with a bill of material (BOM), production process, and quality control expectation to the contract manufacturer to replicate. The hiring company typically focuses on the research and development, marketing, and selling of the products.

If the contract manufacturer is able to dropship the products directly from their warehouse to the end customer, the hiring company would basically be a marketer of the products it developed.

Contract Manufacturing Examples

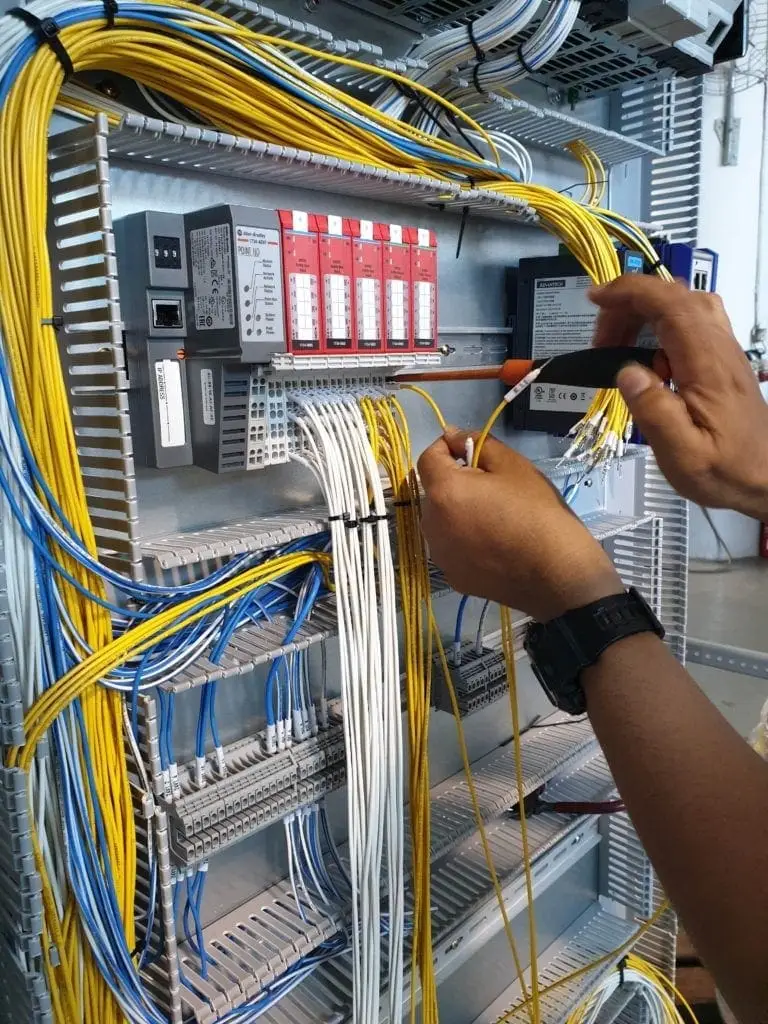

A typical example would be when a machine supplier in the automated production machinery industry contracted with Exxel Technology Pte Ltd, for example, to manufacture wire harness and cable assembly, electromechanical assembly, and control panel on a contract basis for its machines. Exxel Technology is able to serve “Just in Time” needs with speed, engineering expertise, and global sourcing capacity.

Tight fit and tight tolerance build to print requirements are Exxel strengths. Minimum order quantities help Exxel Technology customers hold down inventory costs and get parts as soon as they need them. This provided business for Exxel and maintained the standards and reputation of the hiring company.

Benefits of Contract Manufacturing

Businesses choose contract manufacturing for a few primary reasons, all of which make it easier and cost-effective to introduce and distribute products to the market.

Outsourcing production comes with several benefits.

Not having to invest in a production facility is the biggest cost saving of outsourcing manufacturing. Lower investment in purchasing equipment and machinery and maintaining, repairing or replacing it. The contract manufacturing plant location might also offer savings in energy, logistic cost, and raw material costs as well as tax savings.

Eliminating the need to hire, train and retain train labor to manufacture in-house.

The hiring company is not financially responsible for the contract manufacturers’ staff and equipment. They only need to pay the contracted amount along with any additional fees or charges.

By outsourcing manufacturing to a contract manufacturer, the hiring company can focus on a specific set of tasks, figure out how to increase the productivity of each task, and practice greater budget control across the course of a product’s life cycle.

Contract manufacturers have significantly more resources to quickly scale production needs to match a peak or seasonal decrease in demand. Giving the hiring company the required scalability to meet demand fluctuation.

Contract manufacturing frees up people at the hiring firm to stay focused on their core strengths and competencies when a contract manufacturer takes on a load of manufacturing products for them.

By hiring a contract manufacturer to produce a specific subassembly to supplement the hirer production line, they are able to improve their manufacturing time. This leads to increased speed to market, delivery time, and response to customers’ needs.

The hiring companies maintain consistent production of high-quality products with the help of contract manufacturers. Setting that quality standard will raise brand awareness and ensure market recognition as a reliable supplier. This can also lead to better business relationships with potential customers, partners, and future suppliers.

Risks of Contract Manufacturing

As beneficial as contract manufacturing can be, there are some disadvantages that can come up from outsourcing to produce your parts and products.

Lack of direct control over the quality of the final product may be the biggest disadvantage of outsourcing manufacturing. For the hiring company, there are certain specifications and qualities that are desired for the product. The hiring company has very little control over the product quality until it is presented for review. The hiring company can’t manage what goes on day-to-day and has very little control over the manufacturing and production of the product. It risks losing critical knowledge and skills around production and quality control techniques.

A business that hires a contract manufacturer should understand that it may not be a key customer to the manufacturer hence may not be as important to the manufacturer as other, larger clients.

There is always a risk of hiring a wrong contract manufacturer and product quality may suffer. This can be due to miscommunication, mismanagement of expectation, or a difference in opinion for the production process and/or material which can result in a negative impact on both the clients and manufacturer reputation.

When you outsource your manufacturing, you give the contractor manufacturer access to your intellectual property. An unethical provider may misuse your intellectual property to their own advantage with them potentially becoming your competitor.

How to Choose the Right Contract Manufacturer?

There are some very important characteristics when hiring a contract manufacturer. Finding the right fit can make or break a company’s business and reputation.

The hiring company should only outsource to a contract manufacturer that has expertise in the type of product the company wants to make.

Here are some key points to look for in a contract manufacturer:

- Highly reputable in the marketplace that companies can feel confident in investing in

- Work with a contract manufacturer that understands your specific needs

- A respectable manufacturer who protect your intellectual properties

- Financially sound company

- A clean, well-managed facility, the staff should be experienced and knowledgeable, and an organized, structured production process

- ISO-certified manufacturing quality standards generally provide higher quality parts, components, and products to their clients

- Dropshipping capabilities to send the product directly to the end customers if that's something the business needs

- The ability to quickly react and respond to production demands with little friction or slowdown

- Open communication is critical to establish the expectation of both parties

Contact Exxel Technology for Your Contract Manufacturing Needs

Exxel Technology has established itself as a reputable and recognized contract manufacturer. Customers are able to hold down inventory costs and get parts as soon as they need them because of Exxel’s engineering capability, total build to print solutions, and skilled technicians. We’re happy to discuss the parameters of your manufacturing project, and from there we can see if Exxel is a good fit for your company and vice versa.

Contact the Exxel Technology team today for a no-obligation discussion.